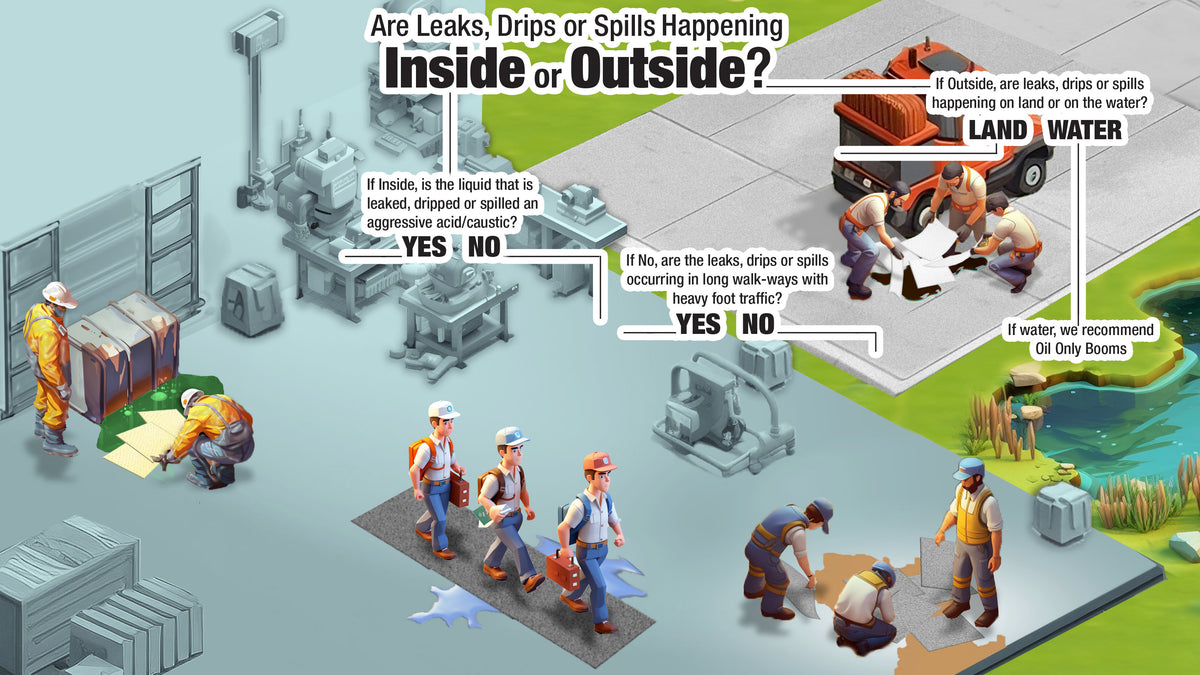

Sorbent Usage Guide

The key to cleaning up any spill is picking the right tool for the job. Below are some common spill control situations and the best solutions for those spills. Simply answer yes or no to questions in descending order till you find the sorbent that fits.